Maattabel

Afmetingen voor Lagerbussen PTFE met kraag in alle beschikbare maten worden getoond volgens de bovenstaande producttekening.

Hulp nodig?

Ons team helpt u graag!

Live chat: Beschikbaar rechtsonder op je scherm.

E-mail:

sales@highperformancepolymer.com

Telefoon: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

Materiaal: PTFE

Measurement System: Metric

Natural

Temperatuur bij continu gebruik: 260°C

Ontvlambaarheid: UL94 V-0

Lagerbussen PTFE met kraag voldoen aan de volgende normen/normen:

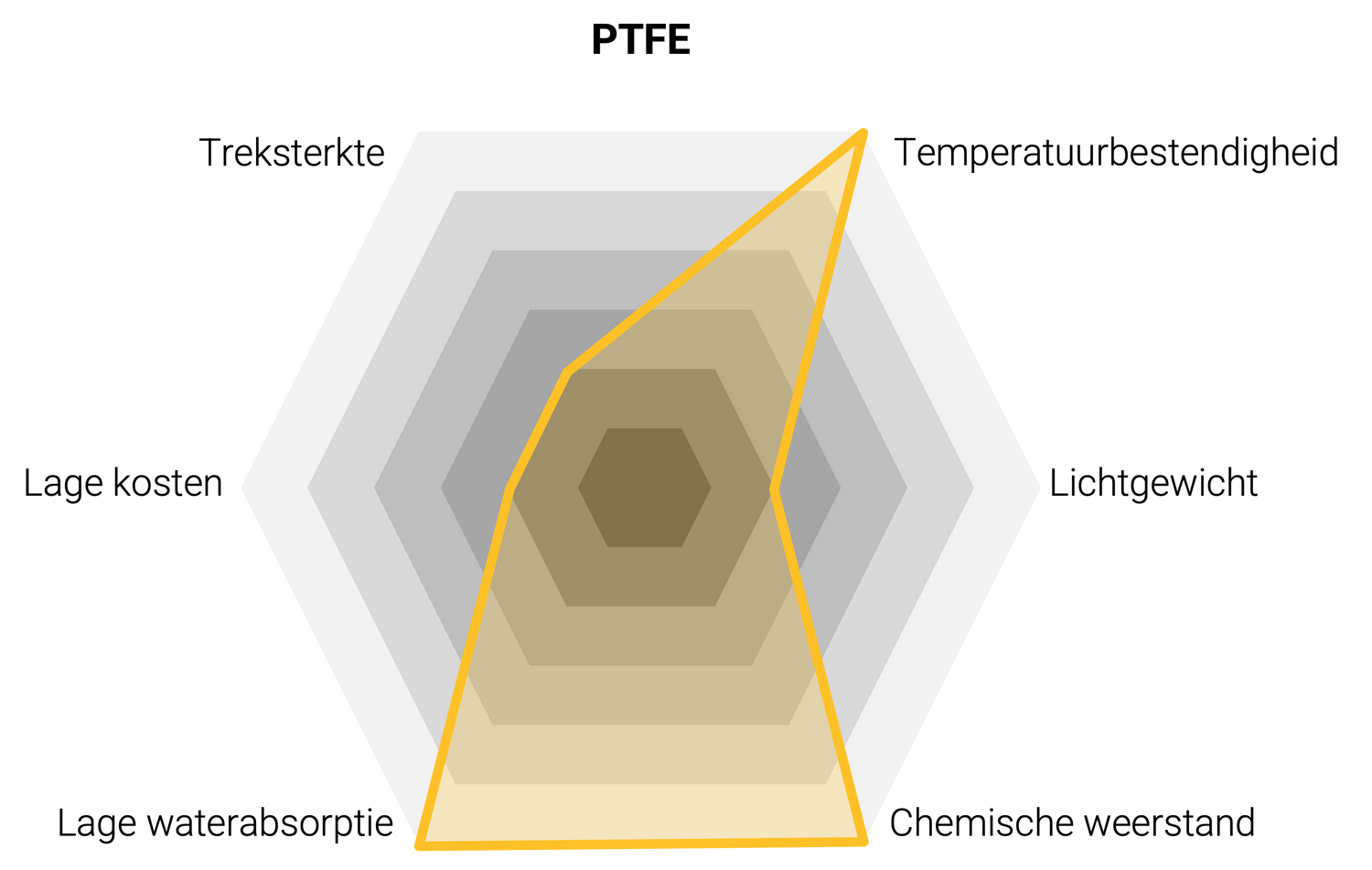

PTFE-flenzen, verkrijgbaar in binnendiameters variërend van 4 mm tot 20 mm, zijn ontworpen voor gebruik in diverse industriële toepassingen vanwege hun uitzonderlijke eigenschappen. Deze flenzen zijn gemaakt van polytetrafluorethyleen (PTFE) en bieden een uitstekende chemische weerstand, tolerantie voor hoge temperaturen en lage wrijvingscoëfficiënten. De niet-reactieve aard van PTFE maakt het geschikt voor de behandeling van corrosieve stoffen, waardoor duurzaamheid en een lange levensduur worden gegarandeerd, zelfs in ruwe omgevingen. Bovendien staan PTFE-flenzen bekend om hun elektrisch isolerende eigenschappen en weersbestendigheid, waardoor ze een ideale keuze zijn voor zowel chemische als elektrische toepassingen.

Binnendiameter (mm) - 4, 5, 5,1, 9,7, 10, 12,7, 15,7, 20

Buitendiameter (mm) - 6, 8, 10, 16, 15, 19,3, 23, 26

Totale lengte (mm) - 5,5, 5,9, 8, 8,8, 9, 11, 16,5, 18, 20, 21,5

Flenzen van polytetrafluorethyleen (PTFE) zijn het toppunt van technische innovatie en staan bekend om hun uitzonderlijke eigenschappen en veelzijdigheid in diverse industrieën. PTFE, een op fluor gebaseerde hars, vertoont een opmerkelijke weerstand tegen chemicaliën en oplosmiddelen, samen met ongeëvenaarde elektrische eigenschappen, antikleefeigenschappen en smering.

Voordelen van PTFE-flenzen:

1. Chemische weerstand: PTFE-flenzen zijn uitstekend bestand tegen een breed scala aan chemicaliën en oplosmiddelen, waardoor ze ideaal zijn voor toepassingen waarbij blootstelling aan corrosieve stoffen gebruikelijk is. Ze behouden hun integriteit, zelfs in aanwezigheid van agressieve zuren, basen en andere corrosieve stoffen, en garanderen betrouwbaarheid op lange termijn.

2. Stabiliteit op hoge temperatuur: PTFE-flenzen blinken uit in omgevingen met hoge temperaturen en behouden hun structurele integriteit en prestaties zelfs bij hoge temperaturen. Deze eigenschap maakt ze geschikt voor gebruik in toepassingen waar thermische stabiliteit van cruciaal belang is, zoals in de chemische industrie, de auto-industrie en de ruimtevaartindustrie.

3. Elektrische isolatie: Met uitstekende elektrische isolerende eigenschappen bieden PTFE-flenzen effectieve isolatie tegen elektrische stromen. Deze eigenschap maakt ze van onschatbare waarde in elektrische en elektronische toepassingen, waar isolatie en diëlektrische sterkte van het grootste belang zijn.

4. Niet-aanbakend oppervlak: De antikleefeigenschappen van PTFE zorgen voor minimale hechting van stoffen aan het flensoppervlak, waardoor wrijving wordt verminderd en schoonmaken gemakkelijker wordt. Deze eigenschap is vooral voordelig in de voedselverwerking, waar de aanhechting van voedseldeeltjes schadelijk kan zijn voor de hygiëne en efficiëntie.

5. Smeerbaarheid: De inherente smering van PTFE vermindert wrijving en slijtage, wat bijdraagt aan een soepele werking en een langere levensduur van mechanische componenten. Deze kwaliteit is voordelig in machines en materiaal waar de wrijving moet worden geminimaliseerd om voorbarige slijtage te verhinderen en efficiency te verbeteren.

Gebruik van PTFE-flenzen:

1. Chemische verwerking: PTFE-flenzen worden op grote schaal gebruikt in chemische verwerkingsapparatuur, waaronder pompen, kleppen en leidingsystemen, waar weerstand tegen corrosieve chemicaliën essentieel is.

2. Elektrotechniek: PTFE-flenzen worden gebruikt in elektrische isolatiecomponenten, zoals isolatoren, schakelaars en stroomonderbrekers, vanwege hun uitstekende diëlektrische eigenschappen.

3. Werktuigbouwkunde: PTFE-flenzen worden gebruikt in diverse mechanische toepassingen, zoals lagers, afdichtingen en pakkingen, waar lage wrijving en hoge temperatuurstabiliteit vereist zijn.

4. Voedingsmiddelen- en farmaceutische industrie: PTFE-flenzen worden gebruikt in voedselverwerkende en farmaceutische apparatuur om te zorgen voor een hygiënische werking en naleving van strenge wettelijke normen.

5. Ruimtevaart en auto-industrie: PTFE-flenzen zijn een integraal onderdeel van lucht- en ruimtevaartsystemen en automobielsystemen en leveren betrouwbare prestaties onder extreme omstandigheden van temperatuur, druk en trillingen.

Het gegevensblad PTFE kan hieronder als PDF worden gedownload.

Retourneer onderdelen binnen 90 dagen voor een volledige terugbetaling. Zie de retourvoorwaarden voor meer informatie.

| Inside Diameter | Outside Diameter (mm) | Flange Diameter (mm) | Overall Length (mm) |

| 4 | 6 | 12 | 8.8 |

| 5 | 8 | 10 | 5.5 |

| 5 | 10 | 14 | 9 |

| 5.1 | 10 | 13 | 5.9 |

| 9.7 | 16 | 20 | 18 |

| 10 | 16 | 20.7 | 18 |

| 12.7 | 15 | 17.5 | 8 |

| 15.7 | 19.3 | 23 | 11 |

| 20 | 23 | 30 | 16.5 |

| 20 | 23 | 30 | 21.5 |

| 20 | 26 | 32 | 20 |

Afmetingen voor Lagerbussen PTFE met kraag in alle beschikbare maten worden getoond volgens de bovenstaande producttekening.

Volg de onderstaande link om onze PTFE datasheet te bekijken. Dit omvat eigenschappen zoals mechanische, elektrische, thermische en chemische weerstand.

Vraag vandaag nog een offerte aan voor onderdelen op maat, speciaal voor jou gemaakt! Vul dit korte formulier in en je ontvangt binnen 24 uur een scherpe, vrijblijvende offerte.

50.000+ bevestigingsartikelen op voorraad

Geen lange levertijden. We hebben een groot assortiment PEEK-bevestigingsartikelen beschikbaar voor expreslevering (dezelfde dag verzonden indien besteld voor 15.00 uur van maandag t/m donderdag).

Bevestigingsartikelen die niet beschikbaar zijn voor expreslevering, tonen de verwachte leverdatum boven de knop 'Toevoegen aan winkelwagentje'.

Fabrikant Directe Distributeur

We zijn een directe distributeur van de fabrikant, waardoor we zeer concurrerende prijzen kunnen garanderen en onze schappen gevuld kunnen houden. Al onze producten zijn vervaardigd volgens de hoogste normen en vertonen uitzonderlijke eigenschappen.

ISO9001 Gecertificeerd

Gecertificeerd door Quality Veritas. High Performance Polymer voldoet aan het ISO9001 kwaliteitsmanagementsysteem. Certificaten beschikbaar op aanvraag.

Materiaalcertificaten

We bieden volledige traceerbaarheid van materialen en kunnen certificeringen leveren die de materiaalgegevens en het batchnummer bevestigen, die kunnen worden getraceerd naar de fabrikant.

Conformiteitscertificaat

Op verzoek leveren we ook een conformiteitscertificaat dat de productienorm en het materiaal bevestigt.