200 Producten

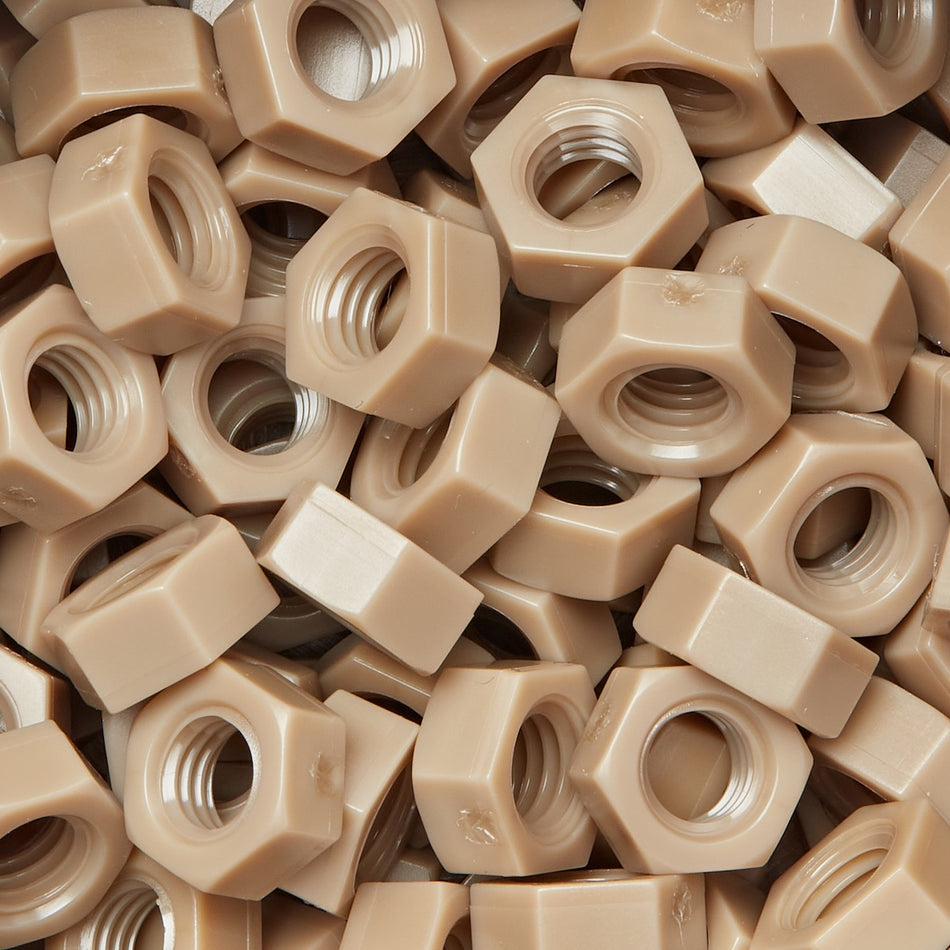

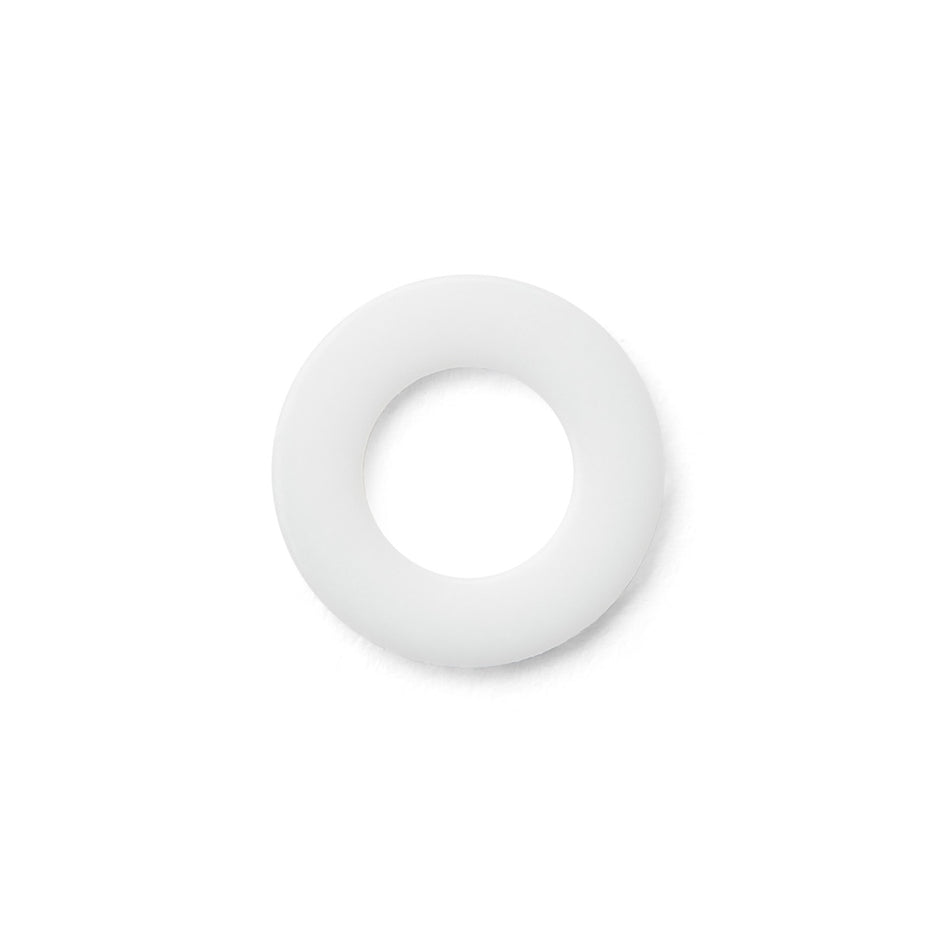

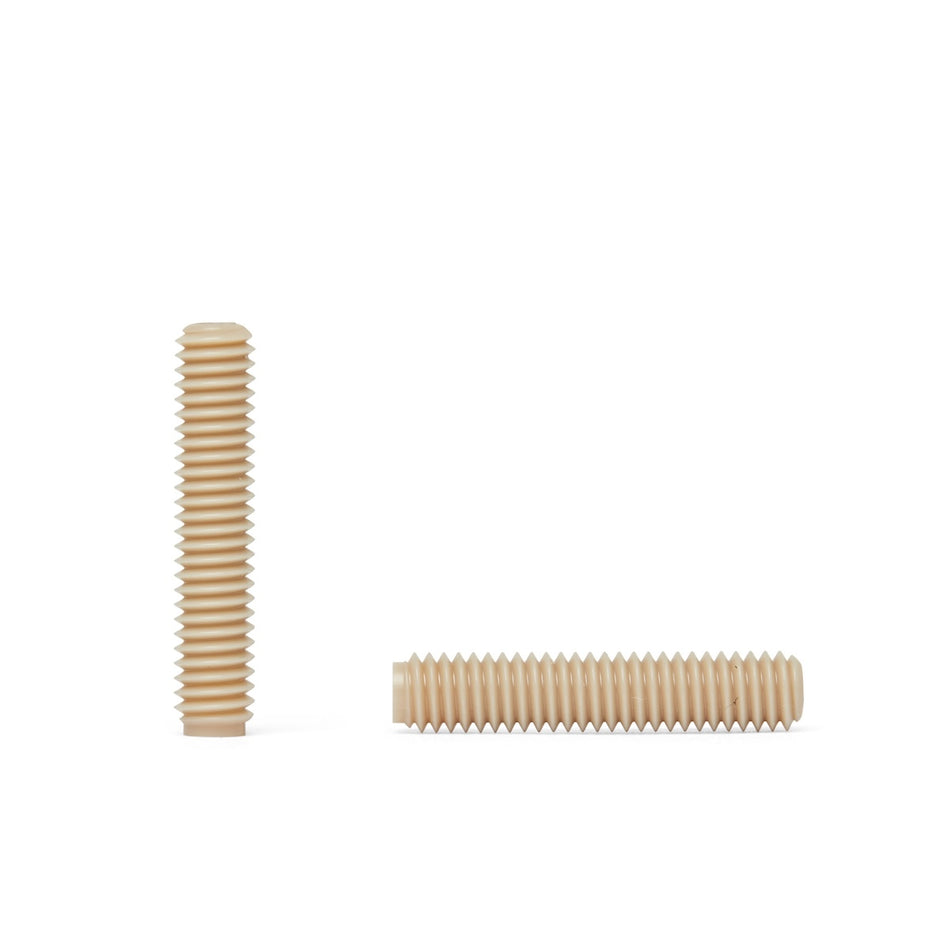

Chemisch bestendige schroeven, moeren, bouten, sluitringen en bevestigingsmiddelen

Why Are Chemical Resistant Fasteners Needed?

Chemical resistant screws, nuts, bolts, washers, and fasteners are an important component in many applications where chemical exposure is a concern, and they can help to extend the service life of fasteners and improve the reliability of equipment and structures in chemically challenging environments.

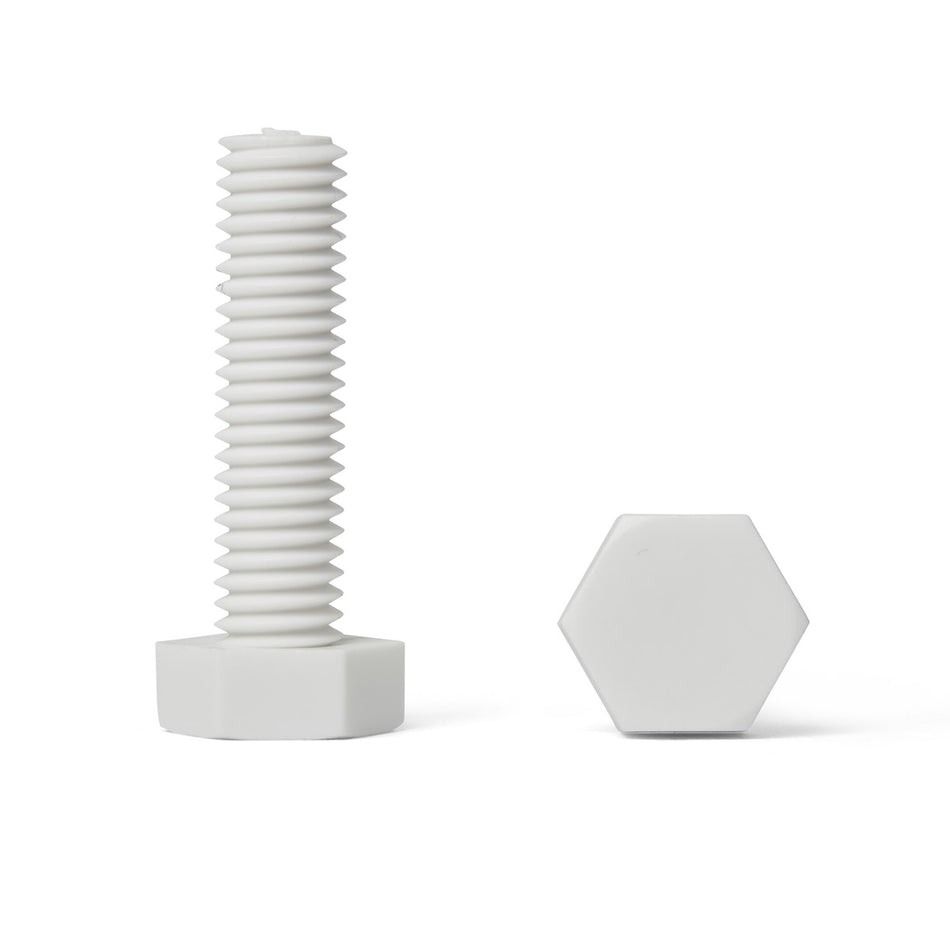

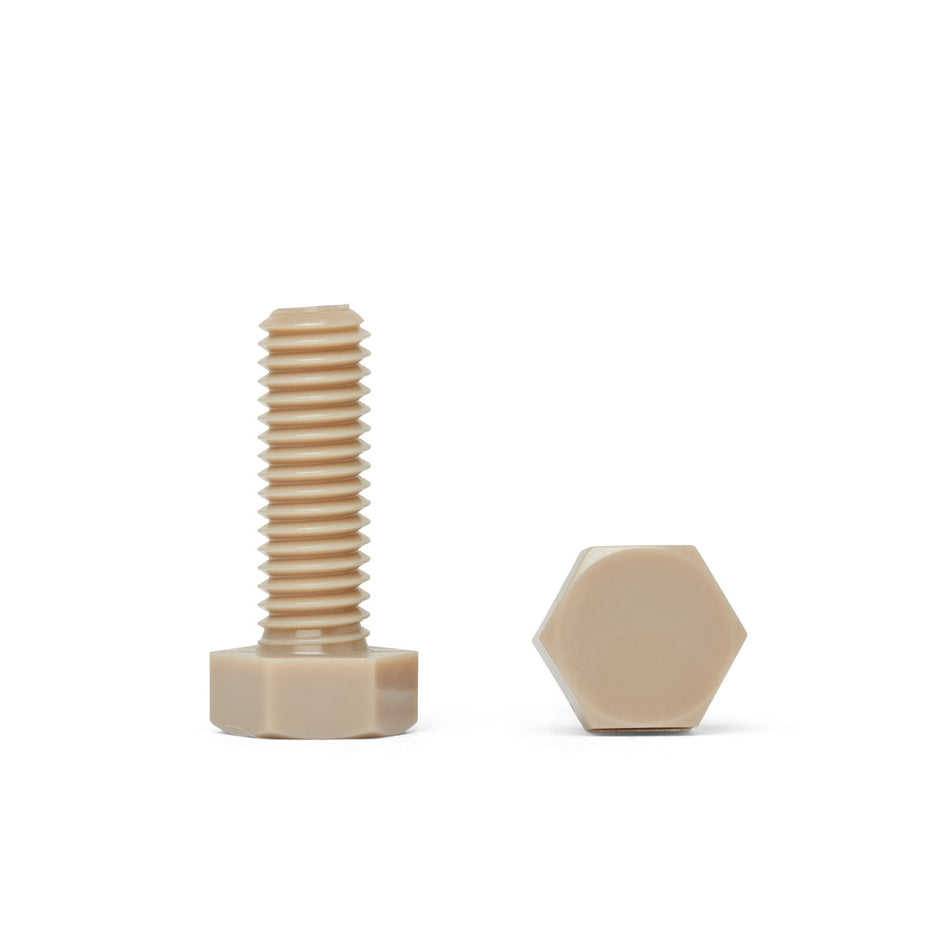

Chemical Resistant Polymer Fasteners

Chemical resistant polymer fasteners are a type of fastener that is made from polymers, or plastic materials, that are resistant to chemical corrosion. These are used in a wide range of applications where exposure to chemicals could be a problem, and they offer several benefits over traditional metallic fasteners.

One of the main benefits of chemical resistant polymer fasteners is their lightweight and easy-to-handle properties. This makes them particularly suitable for use in applications where weight is a concern, such as in the aerospace and automotive industries. Polymer fasteners are also typically easier to install than metal equivalents, as they do not require specialized tools or equipment.

In addition to their lightweight and easy-to-handle properties, chemical resistant polymers offer good electrical insulation properties. This makes them suitable for use in electrical and electronic applications where electrical insulation is important.

There are several types of chemical resistant polymer fasteners, including polyetheretherketone (PEEK), polyvinyl chloride (PVC), and polyvinylidene fluoride (PVDF). PEEK fasteners are known for their excellent mechanical and thermal properties, as well as their resistance to a wide range of chemicals. PVC fasteners are also known for their good mechanical and thermal properties, as well as their resistance to UV light and weathering. PVDF fasteners are known for their excellent chemical resistance, making them suitable for use in corrosive environments.

What are chemical resistant fasteners used for?

Chemical-resistant fasteners are essential in industries where exposure to corrosive substances and harsh environments is frequent. They are widely used in chemical processing plants, refineries, and wastewater treatment facilities, where they ensure the integrity of equipment and structures by resisting degradation from acids, solvents, and other aggressive chemicals. These fasteners are also critical in the pharmaceutical and food industries, where maintaining hygiene and preventing contamination is crucial. In marine applications, chemical-resistant fasteners help prevent corrosion from saltwater, while in the aerospace and automotive sectors, they provide durable solutions for components exposed to extreme conditions.

What Are Chemical Resistant Fasteners?

Chemical resistant screws, nuts, bolts and washers are fasteners that are designed to resist the effects of chemical exposure. They are used in a variety of applications where chemical exposure is a concern, such as in the chemical or pharmaceutical industries, or in environments where corrosive substances are present.

Chemisch resistente schroeven, moeren, bouten, sluitringen en bevestigingsmiddelen zijn bevestigingsmiddelen die ontworpen zijn om de effecten van chemische blootstelling te weerstaan. Ze worden gebruikt in verschillende toepassingen waar blootstelling aan chemische stoffen een probleem is, zoals in de chemische of farmaceutische industrie of in omgevingen waar corrosieve stoffen aanwezig zijn.

Er zijn verschillende manieren om bevestigingsmiddelen chemisch resistent te maken, waaronder het gebruik van chemisch resistente materialen en het aanbrengen van chemisch resistente coatings. Enkele veelgebruikte materialen voor chemisch resistente bevestigingsmiddelen zijn roestvrij staal, messing en brons, evenals bepaalde soorten plastic of polymeer. Deze materialen zijn bestand tegen corrosie en andere soorten chemische degradatie vanwege hun inherente chemische eigenschappen, en ze worden vaak gebruikt in omgevingen waar blootstelling aan chemische stoffen een probleem is.

Naast het gebruik van chemisch bestendige materialen kunnen er ook chemisch bestendige coatings worden aangebracht op bevestigingsmiddelen om een extra beschermingslaag te bieden tegen chemische blootstelling. Deze coatings kunnen worden aangebracht door middel van processen zoals galvaniseren, anodiseren of verven, en ze kunnen helpen om het onderliggende materiaal te beschermen tegen de effecten van chemische blootstelling.

In het algemeen zijn chemisch resistente schroeven, moeren, bouten, sluitringen en bevestigingsmiddelen een belangrijk onderdeel in veel toepassingen waar blootstelling aan chemische stoffen een probleem is. Ze kunnen helpen om de levensduur van bevestigingsmiddelen te verlengen en de betrouwbaarheid van apparatuur en constructies in chemisch veeleisende omgevingen te verbeteren.