Maattabel

Afmetingen voor Lagerbussen PEEK met kraag in alle beschikbare maten worden getoond volgens de bovenstaande producttekening.

Hulp nodig?

Ons team helpt u graag!

Live chat: Beschikbaar rechtsonder op je scherm.

E-mail:

sales@highperformancepolymer.com

Telefoon: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

Materiaal: PEEK

Measurement System: Metric

Natural

Maximale temperatuur: 260°C/500°F

Ontvlambaarheid: UL94 V-0

Lagerbussen PEEK met kraag voldoen aan de volgende normen/normen:

PEEK flenzen, verkrijgbaar met een binnendiameter van 4 mm tot 20 mm, zijn gemaakt van polyether ether ketone (PEEK), een hoogwaardige thermoplast die bekend staat om zijn uitzonderlijke mechanische eigenschappen. PEEK heeft een hoge trek- en druksterkte, een uitstekende thermische stabiliteit en een uitstekende chemische bestendigheid, waardoor deze flenzen ideaal zijn voor gebruik in veeleisende industriële toepassingen. De lage wrijvingscoëfficiënt en slijtvastheid van het materiaal maken het nog geschikter voor toepassingen die een betrouwbare en duurzame afdichting en bevestiging vereisen.

Binnendiameter (mm) - 4, 5, 5,1, 9,7, 10, 12,7, 15,7, 20

Buitendiameter (mm) - 6, 8, 10, 15, 16, 19,3, 23, 26

Totale lengte (mm) - 5,5, 5,9, 8, 8,8, 9, 11, 16,5, 18, 20, 21,5

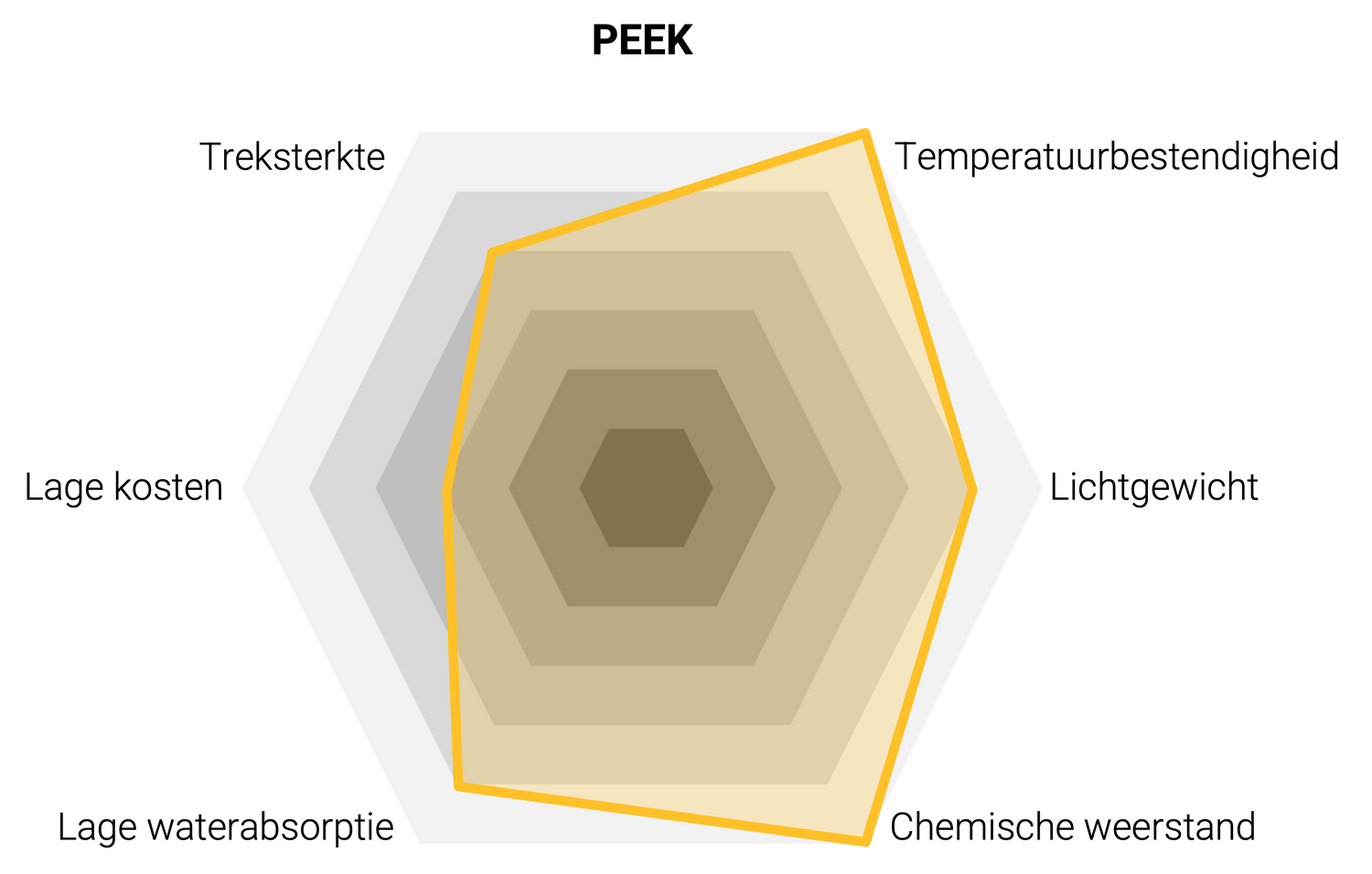

Eigenschappen van GLUUR Flens:

Hoge thermische stabiliteit: GLUUR flenzen zijn bestand tegen hoge temperaturen zonder te vervormen of hun mechanische eigenschappen te verliezen, waardoor ze geschikt zijn voor omgevingen met hoge temperaturen, waaronder chemische verwerking en ruimtevaarttoepassingen.

Chemische bestendigheid: PEEK is zeer goed bestand tegen een breed scala aan chemicaliën, waaronder zuren, basen en organische oplosmiddelen. Deze eigenschap maakt PEEK flenzen ideaal voor gebruik in ruwe chemische omgevingen, waar ze de integriteit en prestaties na verloop van tijd kunnen behouden.

Voordelen van het gebruik van GLUUR flenzen:

Uitzonderlijke Mechanische Sterkte: PEEK biedt een robuuste trek- en druksterkte en zorgt zo voor veilige en stabiele verbindingen in hogedruktoepassingen.

Lage wrijving en slijtvastheid: De lage wrijvingscoëfficiënt van het materiaal vermindert slijtage, waardoor de levensduur van de flens en de bijbehorende onderdelen wordt verlengd.

Elektrische isolatie: PEEK is een uitstekende elektrische isolator, waardoor deze flenzen geschikt zijn voor gebruik in elektronische en elektrische toepassingen waar isolatie vereist is.

Lichtgewicht: PEEK flenzen zijn aanzienlijk lichter dan metalen alternatieven, wat helpt om het totale gewicht van assemblages en systemen te verminderen.

Stralingsbestendigheid: De stralingsbestendigheid van PEEK maakt deze flenzen geschikt voor gebruik in medische en ruimtevaarttoepassingen waar blootstelling aan straling een punt van zorg is.

Biocompatibiliteit: GLUUR is biocompatibel, toestaand het om in medische toepassingen, met inbegrip van implants en hulpmiddelen worden gebruikt.

Specifieke Toepassingen van PEEK Flenzen:

Chemische Verwerking:

Gebruikt in pijpen en montage voor chemische verwerkingsinstallaties, waar de hoge chemische weerstand en de temperatuurstabiliteit kritiek zijn.

Ideaal voor gebruik in systemen die agressieve chemicaliën verwerken, lekkages voorkomen en de integriteit van het systeem behouden.

Ruimtevaart:

Wordt gebruikt in vliegtuig- en ruimtevaartsystemen en biedt lichtgewicht en duurzame oplossingen voor omgevingen met hoge temperaturen en hoge druk.

Gebruikt in brandstofsystemen, hydraulische systemen en andere kritieke onderdelen waar gewichtsbesparing en prestaties essentieel zijn.

Medische apparaten:

Gebruikt in medische apparatuur en implantaten vanwege de biocompatibiliteit en weerstand tegen sterilisatieprocessen.

Ideaal voor gebruik in chirurgische instrumenten en diagnoseapparatuur waar precisie en betrouwbaarheid essentieel zijn.

Automobielindustrie:

Toegepast in autosystemen, vooral in motorcompartimenten en uitlaatsystemen, waar hoge temperatuur en chemische weerstand vereist zijn.

Geschikt voor gebruik in hybride en elektrische voertuigsystemen, voor isolatie en duurzaamheid.

PEEK flenzen, verkrijgbaar met een binnendiameter van 4 mm tot 20 mm, bieden een uitzonderlijke mechanische sterkte, chemische weerstand en thermische stabiliteit, waardoor ze ideaal zijn voor een breed scala aan toepassingen, waaronder chemische verwerking, lucht- en ruimtevaart, medische apparatuur en de auto-industrie. De hoge thermische stabiliteit en chemische weerstand zorgen ervoor dat deze flenzen betrouwbaar presteren onder zware omstandigheden, terwijl voordelen als lage wrijving, slijtvastheid en lichtgewicht hun nut verder vergroten. Of ze nu worden gebruikt in kritische systemen of veeleisende omgevingen, PEEK-flenzen bieden duurzame en betrouwbare oplossingen voor afdichtings- en bevestigingsbehoeften.

Het gegevensblad PEEK kan hieronder als PDF worden gedownload.

Retourneer onderdelen binnen 90 dagen voor een volledige terugbetaling. Zie de retourvoorwaarden voor meer informatie.

| Inside Diameter | Outside Diameter (mm) | Flange Diameter (mm) | Overall Length (mm) |

| 4 | 6 | 12 | 8.8 |

| 5 | 8 | 10 | 5.5 |

| 5 | 10 | 14 | 9 |

| 5.1 | 10 | 13 | 5.9 |

| 9.7 | 16 | 20 | 18 |

| 10 | 16 | 20.7 | 18 |

| 12.7 | 15 | 17.5 | 8 |

| 15.7 | 19.3 | 23 | 11 |

| 20 | 23 | 30 | 16.5 |

| 20 | 23 | 30 | 21.5 |

| 20 | 26 | 32 | 20 |

Afmetingen voor Lagerbussen PEEK met kraag in alle beschikbare maten worden getoond volgens de bovenstaande producttekening.

Volg de onderstaande link om onze PEEK datasheet te bekijken. Dit omvat eigenschappen zoals mechanische, elektrische, thermische en chemische weerstand.

Vraag vandaag nog een offerte aan voor onderdelen op maat, speciaal voor jou gemaakt! Vul dit korte formulier in en je ontvangt binnen 24 uur een scherpe, vrijblijvende offerte.

50.000+ bevestigingsartikelen op voorraad

Geen lange levertijden. We hebben een groot assortiment PEEK-bevestigingsartikelen beschikbaar voor expreslevering (dezelfde dag verzonden indien besteld voor 15.00 uur van maandag t/m donderdag).

Bevestigingsartikelen die niet beschikbaar zijn voor expreslevering, tonen de verwachte leverdatum boven de knop 'Toevoegen aan winkelwagentje'.

Fabrikant Directe Distributeur

We zijn een directe distributeur van de fabrikant, waardoor we zeer concurrerende prijzen kunnen garanderen en onze schappen gevuld kunnen houden. Al onze producten zijn vervaardigd volgens de hoogste normen en vertonen uitzonderlijke eigenschappen.

ISO9001 Gecertificeerd

Gecertificeerd door Quality Veritas. High Performance Polymer voldoet aan het ISO9001 kwaliteitsmanagementsysteem. Certificaten beschikbaar op aanvraag.

Materiaalcertificaten

We bieden volledige traceerbaarheid van materialen en kunnen certificeringen leveren die de materiaalgegevens en het batchnummer bevestigen, die kunnen worden getraceerd naar de fabrikant.

Conformiteitscertificaat

Op verzoek leveren we ook een conformiteitscertificaat dat de productienorm en het materiaal bevestigt.